OEM 65° steel milling cutter tungsten steel hard alloy 4 Flutes round ikhala R umphetho

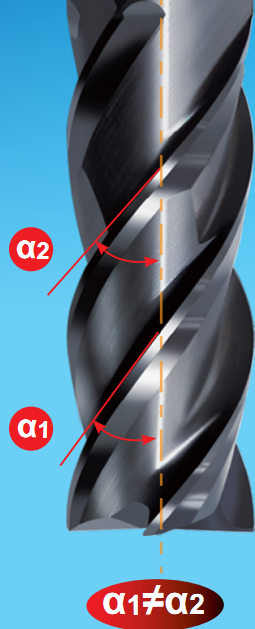

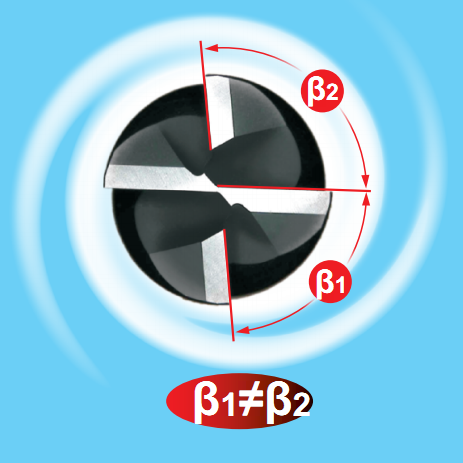

Imiklamo eyingqayizivele njengalena

Isicelo

Ifanele ukucutshungulwa okuseceleni, ukucutshungulwa kwesinyathelo, ukucutshungulwa komsele ongakwesokudla.Ine-ALTIN enamathelayo, elungele kakhulu ukucubungula insimbi ye-carbon steel, i-alloy iron, i-cast iron, i-ductile iron, insimbi eqinisiwe ngaphambili, insimbi ecishiwe (~40/50/55HRC), ingase futhi isetshenziselwe ukucubungula insimbi engagqwali, i-titanium alloy, kanye ingxubevange engashisi.

Imininingwane

Lo mkhiqizo uza ngokucaciswa okuningi namamodeli, onamafluti angu-4 nama-engeli amabili we-helix angu-37 ° no-40 °.

Imifanekiso ye-ZBM4FR

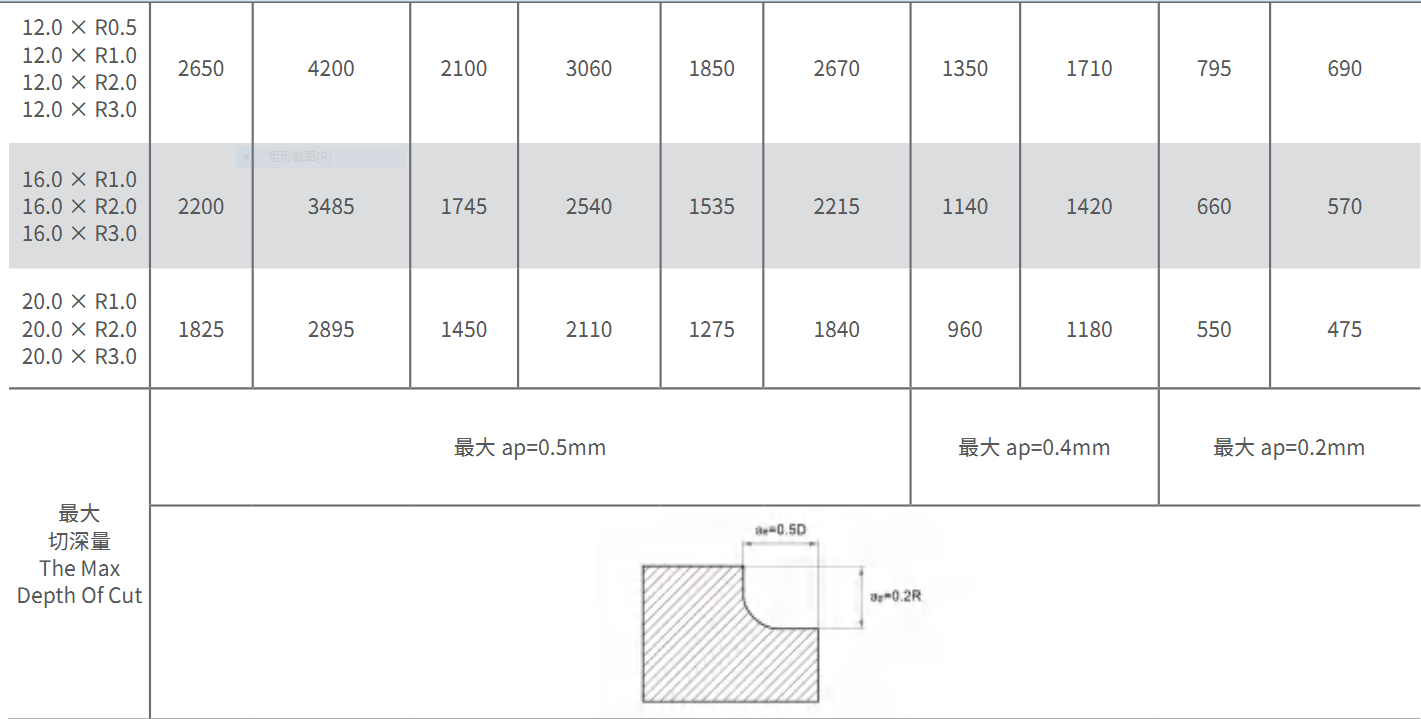

1, Ngaphansi kwezimo ezijwayelekile

1. Ithebula elingenhla yinani elijwayelekile le-side iron machining.Lapho wenza ama-grooves ngethuluzi, isivinini sokujikeleza kufanele sibe ngu-50-70% wethebula elingenhla, futhi isivinini sokuphakelayo kufanele sibe ngu-40-60% njengenani elijwayelekile.

2. Sicela usebenzise amathuluzi omshini anemba okuphezulu nezibambo zamathuluzi.

3. Sicela usebenzise ukupholisa umoya noma uketshezi lokusika olungajwayele ukuphehla intuthu.

4. Ukusika okubushelelezi kunconywa ukusika ohlangothini.

5. Uma ukuqina kokufakwa kwethuluzi lomshini kungalungile, ukudlidliza nomsindo ongajwayelekile kungenzeka.Ngalesi sikhathi, isivinini nesivinini sokuphakela kuleli thebula elingenhla kufanele sehliswe unyaka nonyaka.

6. Ubude bokumiswa komsiki kufanele bube bufushane ngangokunokwenzeka.

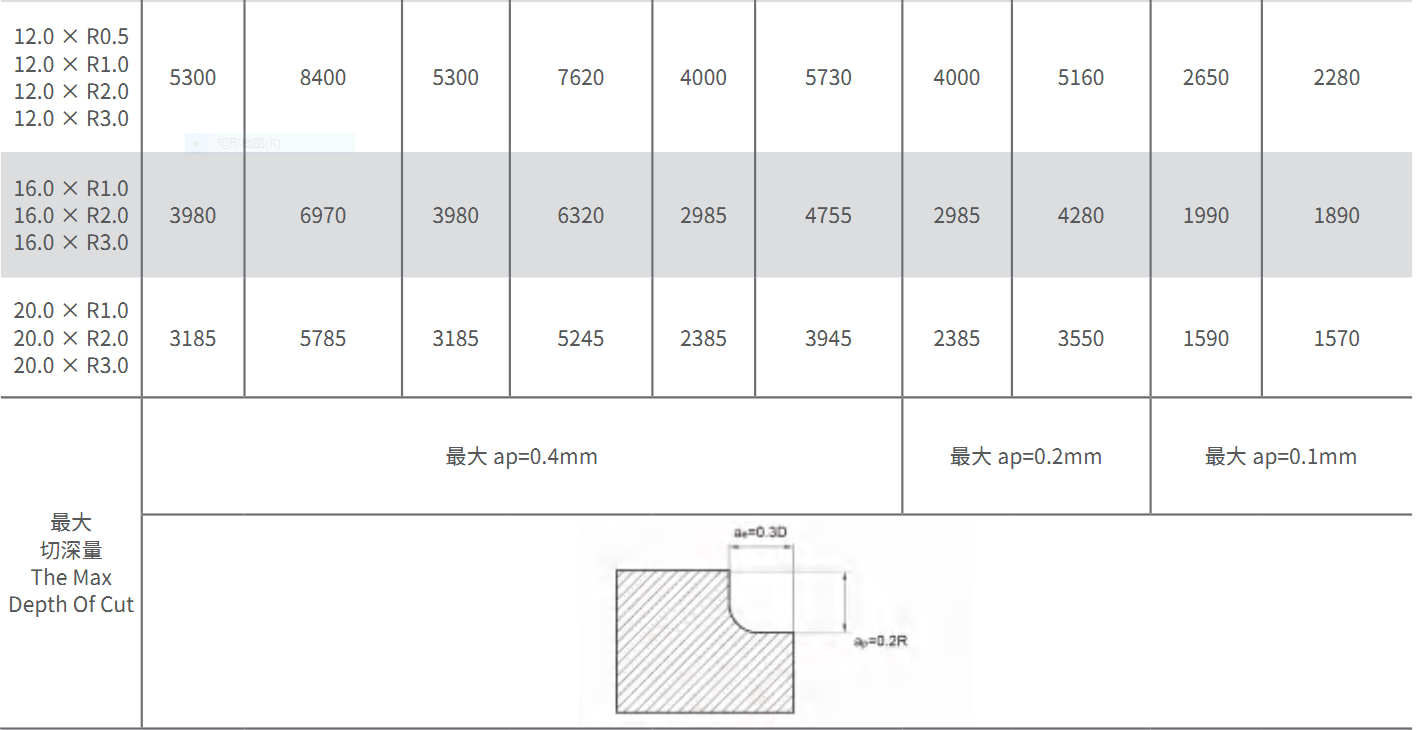

2. Ngaphansi kwezimo zesivinini esikhulu

1. Ithebula elingenhla yinani elijwayelekile le-side iron machining.Lapho wenza ama-grooves ngethuluzi, isivinini sokujikeleza kufanele sibe ngu-50-70% wethebula elingenhla, futhi isivinini sokuphakelayo kufanele sibe ngu-40-60% njengenani elijwayelekile.

2. Sicela usebenzise amathuluzi omshini anemba okuphezulu nezibambo zamathuluzi.

3. Sicela usebenzise ukupholisa umoya noma uketshezi lokusika olungajwayele ukuphehla intuthu.

4. Ukusika okubushelelezi kunconywa ukusika ohlangothini.

5. Uma ukuqina kokufakwa kwethuluzi lomshini kungalungile, ukudlidliza nomsindo ongajwayelekile kungenzeka.Ngalesi sikhathi, isivinini nesivinini sokuphakela kuleli thebula elingenhla kufanele sehliswe unyaka nonyaka.

6. Ubude bokumiswa komsiki kufanele bube bufushane ngangokunokwenzeka.