Izigayo ze-OEM 3/4 Flutes End ezine-Straight Shank kanye ne-Wave Cutting Edges

Isicelo

Izigayo ezi-3 ze-Flutes End ezine-Straight Shank kanye ne-Wave Cutting Edges zilungele ukwenziwa kwe-aluminium alloys, kanye nomshini oseceleni, umshini wezinyathelo, kanye ne-right angle groove machining.Futhi izigayo ezi-4 ze-Flutes End ezine-Straight Shank kanye ne-Wave Cutting Edges zilungele ukucubungula insimbi ye-carbon steel, i-alloy steel, i-cast iron, i-ductile iron, insimbi eqinisiwe ngaphambili, insimbi ecishiwe (~40HRC)l, njll. Ifanele ukucutshungulwa eceleni, ukucutshungulwa kwesinyathelo, kanye nokucutshungulwa kwe-engeli yesokudla.

Imininingwane

Impahla yokukhiqiza yokukhiqiza isigayo sokuphela kwemitshingo engu-3 yi-UK10, enama-milling cutters atholakala ngobubanzi obusuka ku-6 mm kuya ku-20 mm, kanye nobude bethuluzi obuphelele busuka ku-50 mm kuya ku-100 mm.I-angle ejikelezayo ye-clutter ingama-degrees angu-45.

Izinto ezisetshenziswayo zokukhiqiza isigayo sokuphela kwemitshingo engu-4 yi-UK30, ehlanganiswe ne-ATN.I-angle evunguzayo ye-clutter ingama-degrees angu-30, kanti ububanzi bangaphandle bomshini wokusika butholakala ku-6 mm kuya ku-20 mm.Ubude obuphelele bomsiki buyi-50 mm kuya ku-100 mm.

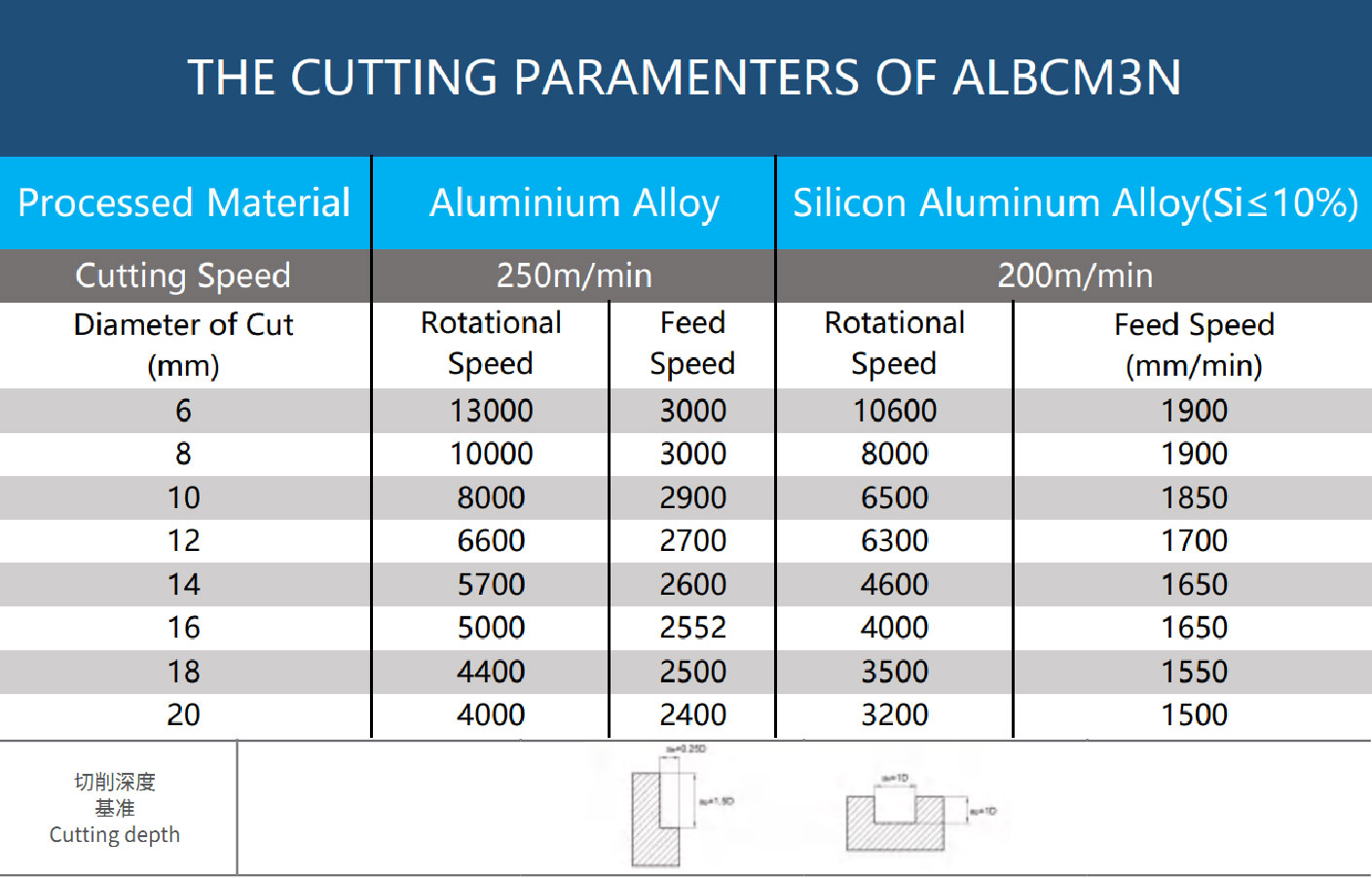

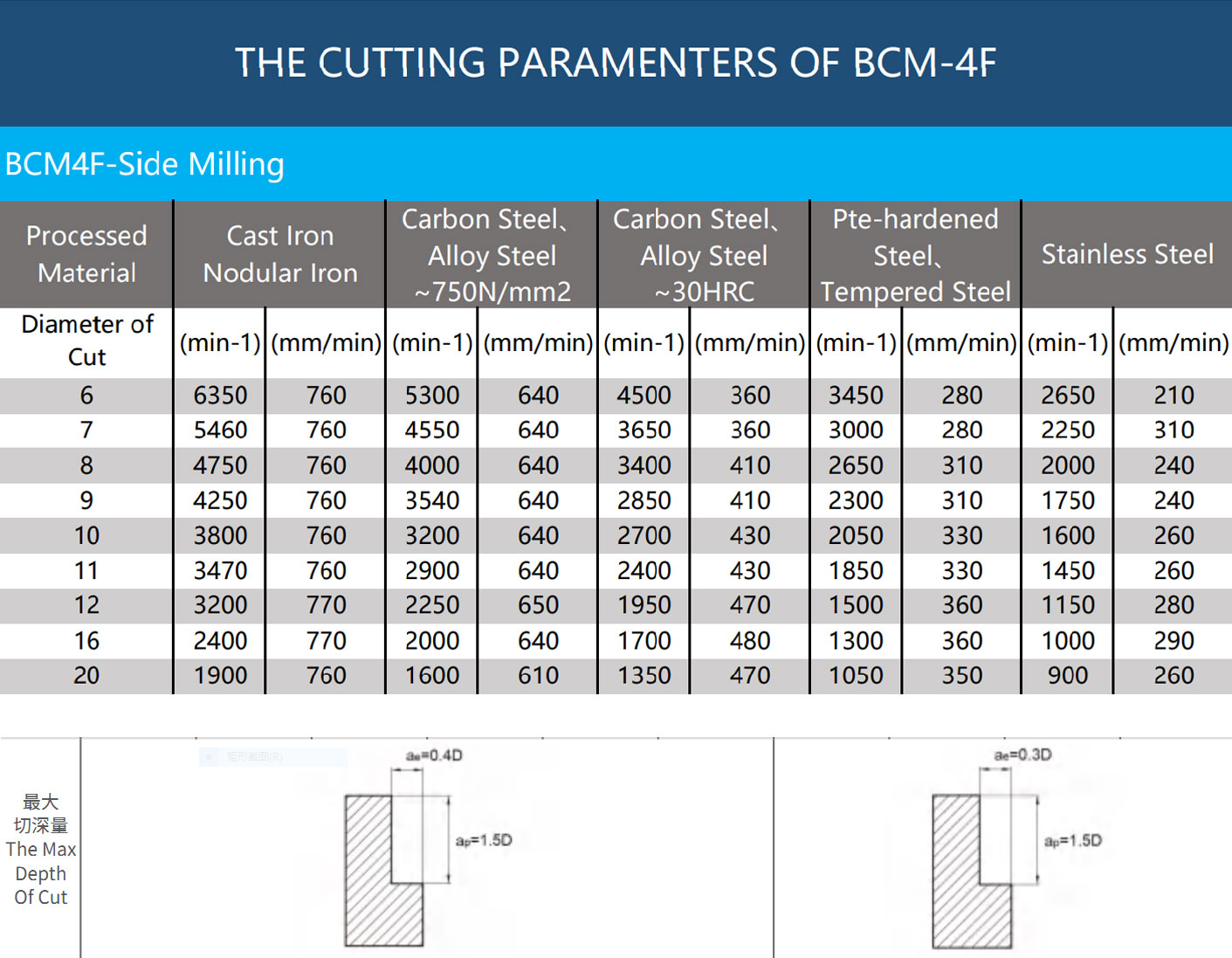

Amapharamitha wokusika we-ALBCM3N / BCM4F

1. Uma ukujula kokusika kukuncane, isivinini sokujikeleza kanye nesivinini sokuphakela singathuthukiswa nakakhulu

2. Kunconywa amanzi okusika amanzi ancibilikayo

3. Ukugaywa komhlaba kuyanconywa

4 .Esimeni somshini nokufakwa kwe-workpiece rigidity impofu, ezokhiqiza ukudlidliza nomsindo ongajwayelekile, kuleli phuzu kufanele kusheshise isivinini kanye nesivinini sokuphakelayo.

5. Ubude bokumiswa komsiki kufanele bube bufushane ngangokunokwenzeka.

6. Ithebula eliphezulu lisekelwe enanini eliyinkomba lokusika ohlangothini.Izimo zokusika ze-slot milling zisekelwe ku-70% wejubane lokusika etafuleni elingenhla kanye no-50% wejubane lokuphakelayo.

1. Sicela usebenzise amathuluzi omshini anemba okuphezulu nezibambo zamathuluzi.

2. Sicela usebenzise ukupholisa umoya noma uketshezi lokusika olungajwayele ukuphehla intuthu.

3. Ukusika okubushelelezi kunconywa ukusika ohlangothini.

4. Uma ukuqina kokufakwa kwethuluzi lomshini kungalungile, ukudlidliza nomsindo ongajwayelekile kungenzeka.Kulokhu

isikhathi, isivinini kanye nesivinini sokuphakelayo kuthebula elingenhla kufanele kwehliswe unyaka nonyaka.

5. Ubude bokumiswa komsiki kufanele bube bufushane ngangokunokwenzeka.